Snap-in Subminiature (620 Series)

Snap-in Miniature (720 Series)

Bayonet NCC Subminiature (670 Series)

Bayonet NCC Miniature (770 Series)

RD24 Power (692 | 693 Series)

IP67 RJ45 Industrial Ethernet Series

M8 A-Coded Series

M8 A-Coded Series

M12 Series

M12 Stainless Steel Series

7/8" Series

7/8" Series

M23 Signal Series

M23 Power & Hybrid Series

Han Food & Beverage Series

Har-Port Series

M12 Power Series

M16 Signal & Power Series

M23 Fast Ethernet PoE Series

M16 & M23 Stainless Steel Connector Housing Series

M27 Signal Series

M40 Power Series

M12 A-Coded Series

M12 X-Coded Series

Circular Connectors from Northern Connectors

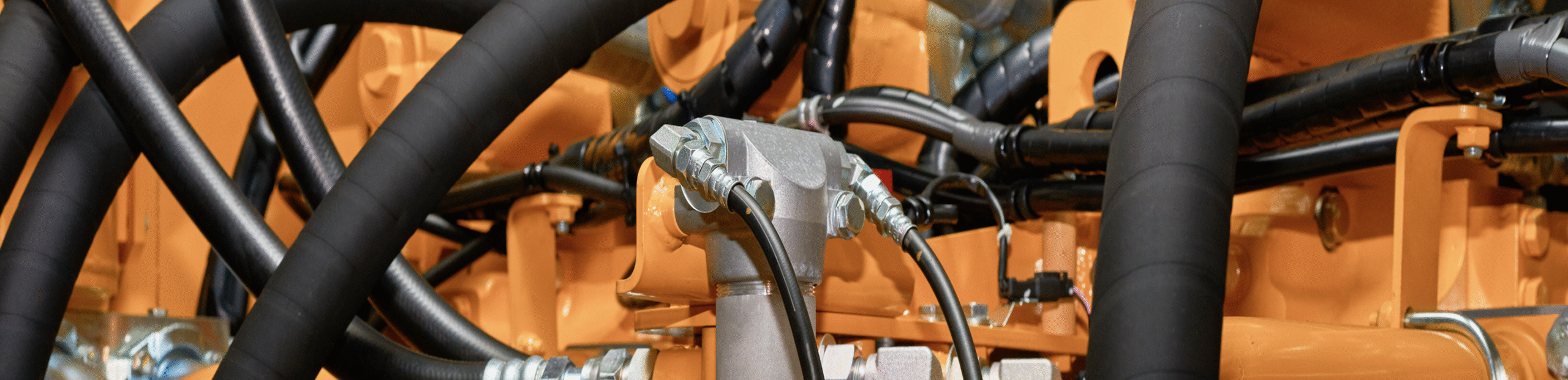

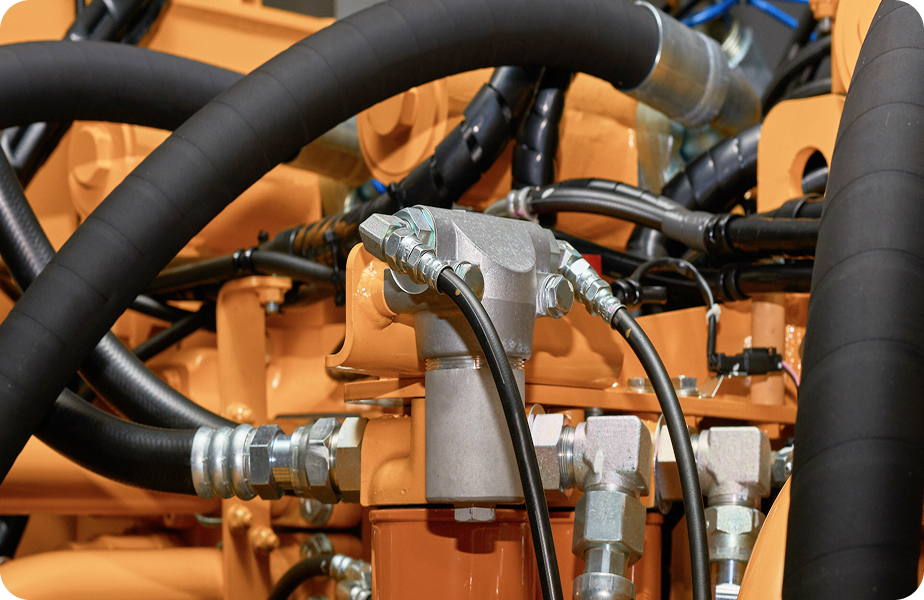

If you’re searching for a high-performance terminal to connect cables in a site that may involve high pressures, vibrations, temperature shocks, or similar kinds of mechanical turbulence, then look no further than our circular connectors. The same applies if you need industrial cable connectors that are protected against interference from electromagnetic signals.

Of course, these high levels of protection also enable our extremely resilient circular connectors to withstand moisture and water, dirt and dust, and other particles that may otherwise get inside and potentially damage the cables within the connector.

We have a large selection of circular connectors available with next-day delivery, with a variety of IP ratings and mating styles, as well as miniature and sub-miniature versions. Whether you need snap-in or push-pull connectors, sew termination, bayonet connectors, panel-mounted or board-mounted connectors, you’re sure to find exactly what functionality you need for your project.

We also supply hybrid circular connectors, which conveniently connect both power circuits and signal circuits using a single shell.

What are the benefits of circular connectors?

Circular connectors have become widely adopted across a range of industries due to their robust design, ease of use, broad range of configurations and extreme versatility. Consisting of multi-pin inserts sat within a robust mechanical housing with a circular design, they are capable of efficiently transmitting data, signal and power.

These versatility of circular connectors and their broad range of benefits and useful attributes have helped them become an indispensable industry standard:

- Easy to install and remove

- Compact designs

- Reliable and secure locking mechanisms

- Sealed ingress protection up to IP68 & IP69K

- Capable of housing various kinds of contact within the same shell

Order our circular connector product range

If you require high-quality circular connectors suitable for a comprehensive range of industrial applications, browse the wide selection on offer at Northern Connectors. We stock the very best circular connectors from the industry’s leading brands, delivering top-quality service every time.

Choose from a versatile product range of robust and easy-to-use circular connectors from top manufacturers including Binder, Hirschmann, Hummel, Lumberg Automation and Souriau, with various types of locking mechanism, termination methods, and configurations to suit your needs. No matter what your application may be, we can help find the right product for you.

We are an ISO 9001-certified business with more than 35 years of industry experience, meaning you can rely on quality service from start to finish. We provide next-day delivery on in-stock items and have a low minimum order value to suit your individual requirements, as well as flexible call-off and scheduled order arrangements.

Industrial sectors

Circular connectors are widely used in the following industrial sectors:

- Agriculture

- Audio

- Automotive

- Broadcasting

- Food & Beverage

- Lighting Technology

- Marine

- Medical & Pharmaceutical

- Monitoring, Measurement & Control

- Oil & Gas

- Rail

- Renewable Energy

- Sensor, Automation & Robotics

- Surveillance

Frequently Asked Questions

What are circular connectors?

Also known as ‘circular interconnects’, circular connectors are essentially what their name suggests – cylindrical mechanical shells used to connect cables in the form of multi-pin connectors. They ensure that data and power can be continuously transmitted safely between devices.

Circular connectors have been manufactured and implemented to deliver vital electrical signals that keep complicated systems and machinery running as they should, especially in demanding environments where their hardwearing design offers essential protection.

The cylindrical design of circular connectors allows them to reliably deliver a continuous stream of data and power without the cables becoming misaligned and accidentally decoupling, or being damaged by surrounding elements.

The contacts of a circular connector are typically made from oxygen-resistant metals like steel or brass, which can also be plated with another metal to improve their electrical conductivity, while the shell that houses and seals is often made from a resilient insulating material like moulded plastic or rubber.

How do circular connectors work?

Also known as ‘circular interconnects’, circular connectors are essentially what their name suggests – cylindrical mechanical shells used to connect cables in the form of multi-pin connectors. They ensure that data and power can be continuously transmitted safely between devices.

Circular connectors have been manufactured and implemented to deliver vital electrical signals that keep complicated systems and machinery running as they should, especially in demanding environments where their hardwearing design offers essential protection.

The cylindrical design of circular connectors allows them to reliably deliver a continuous stream of data and power without the cables becoming misaligned and accidentally decoupling, or being damaged by surrounding elements.

The contacts of a circular connector are typically made from oxygen-resistant metals like steel or brass, which can also be plated with another metal to improve their electrical conductivity, while the shell that houses and seals is often made from a resilient insulating material like moulded plastic or rubber.

Which type of circular connector do I need?

Also known as ‘circular interconnects’, circular connectors are essentially what their name suggests – cylindrical mechanical shells used to connect cables in the form of multi-pin connectors. They ensure that data and power can be continuously transmitted safely between devices.

Circular connectors have been manufactured and implemented to deliver vital electrical signals that keep complicated systems and machinery running as they should, especially in demanding environments where their hardwearing design offers essential protection.

The cylindrical design of circular connectors allows them to reliably deliver a continuous stream of data and power without the cables becoming misaligned and accidentally decoupling, or being damaged by surrounding elements.

The contacts of a circular connector are typically made from oxygen-resistant metals like steel or brass, which can also be plated with another metal to improve their electrical conductivity, while the shell that houses and seals is often made from a resilient insulating material like moulded plastic or rubber.

Why choose us?

At Northern Connectors, we combine an unbeatable range of circular connectors with industry-leading customer service. We work closely with many of the sector’s most trusted manufacturers to provide customers from all industries with the products they need, when they need them.

With more than 35 years of industry experience on our side, we are able to offer responsive, tailored customer support according to your requirements, and can advise you on any queries you might have. Here are some of the benefits of shopping with Northern Connectors:

What Connector Type Are You Looking For?

Easily find the connection type you need through the categories below:

Get in touch with our connector experts

With over 40 years experience in the industry, we're always happy to share our knowledge and help with connector solutions or product enquiries.

Whether you want to share your specs or already know the connector you require, we're here to advise.