D-Sub Standard & High Density Series

D-Sub Combination Series

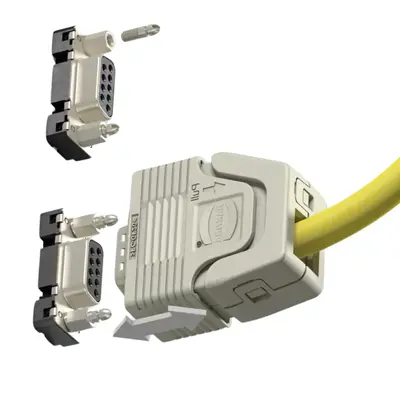

IP67 Waterproof D-Sub Standard & High Density Series

IP67 Waterproof D-Sub Combination Series

D-Sub Hoods & Accessories

D-Sub Connectors, Housings & Accessories

D-Sub Connector SnapLock Hoods

D-Sub Connector PushPull Hoods

D-Sub Connectors, Backshells & Accessories

Despite many technological advances allowing for newer types of connectors, D-sub connectors are still a popular choice due to their reliability and affordability. When you need a straightforward yet robust connector for media, on-the-go, or DIY electronic applications, the D-sub is still a go-to choice for many people around the world.

If you count yourself as one of them, you’ve come to the right place to purchase D-sub connectors. We supply both standard and high-density D-sub connectors with 2–78 pin counts, as well as waterproof D-sub connectors with IP65–IP67 ratings.

For applications that require multiple types of connection inside one shell, we also supply combination D-sub connectors, suitable for commercial and industrial use.

Alternatively, if you’re looking for D-sub hoods, D-sub backshells, or related D-sub connector accessories for additional environmental protection, we can also provide a growing range of extras here at Northern Connectors.

What are the benefits of D-sub connectors?

D-subs were the most effective connectors when they first entered the market in the 1950s, but newer technological developments have led to them being superseded by smaller and sleeker alternatives like USB ports.

While D-sub connectors may not seem like the most up-to-date choice, they still remain a market staple due to their stability in environments that require a more rugged connector. Rather than modern lightweight consumer electronics, D-sub connectors are better suited to commercial and industrial environments.

D-sub miniature connectors are still small enough to fit into tighter spaces, but they’re sturdy enough to remain in position and maintain a connection for a long time without interruption. The way that they’re designed works well with locking mechanisms, allowing the components to stay ‘mated’ with higher resistance to vibrations, jostling, or tampering that might otherwise cause the connector to work loose and disrupt the connection.

This is especially true in cases where the D-sub connector has a backshell to provide extra protection and strain relief on the inserted cable.

Which brands create D-sub connectors?

Northern Connectors represents Conec and Harting, the industry’s top manufacturers of D-sub connectors, with a huge array of choices in their portfolios, including:

- Standard

- High-density

- Combination

- Filter

- Waterproof

In addition, due to the diversity of applications in the industrial market, each manufacturer offers a comprehensive line of D-sub hoods/backshells and accessories.

Order D-sub connectors online

Northern Connectors is a specialist distributor of an extensive range of D-subminiature connectors, backshells, and accessories, which are suitable for use in a wide spectrum of environments and applications.

We stock a wide variety of D-sub connectors, backshells, and accessories from premium brands CONEC and HARTING. Whatever your current specifications may be, Northern Connectors can help you to find the ideal solution.

With more than 35 years’ of experience in supplying industrial connectors and components, we are more than happy to help meet your requirements. We are a family-run, ISO 9001-certified business, and are able to offer flexible call-off and scheduled order arrangements as needed.

Frequently Asked Questions

What is a D-sub connector?

The D-sub connector is one of the most common types of electronic connector in the world. Despite being a basic input/output connector, D-sub miniature connectors can be surprisingly versatile. The name comes from the characteristic shape, which looks like the letter ‘D’.

D-sub connectors feature this D-shaped metal housing as a shield around rows of contacts, which are aligned to match equivalent sockets in the mating half. They typically have two parallel rows of pins or sockets, though there can be more.

When plugged in, this connector then facilitates the transfer of data between two points – however, they’re designed to only work one way, which is why D-sub connectors are considered to be polarised connectors.

The ‘D’ shape ensures that you cannot insert the connector the wrong way, making it easier to plug in the connector and establish a connection. It also offers mechanical support to the contacts inside and screens them against interfering electromagnetic signals.

What are the benefits of D-sub connectors?

D-subs were the most effective connectors when they first entered the market in the 1950s, but newer technological developments have led to them being superseded by smaller and sleeker alternatives like USB ports.

While D-sub connectors may not seem like the most up-to-date choice, they still remain a market staple due to their stability in environments that require a more rugged connector. Rather than modern lightweight consumer electronics, D-sub connectors are better suited to commercial and industrial environments.

D-sub miniature connectors are still small enough to fit into tighter spaces, but they’re sturdy enough to remain in position and maintain a connection for a long time without interruption. The way that they’re designed works well with locking mechanisms, allowing the components to stay ‘mated’ with higher resistance to vibrations, jostling, or tampering that might otherwise cause the connector to work loose and disrupt the connection.

This is especially true in cases where the D-sub connector has a backshell to provide extra protection and strain relief on the inserted cable.

What are D-subminiature connectors used for?

D-subminiature connectors, backshells, and accessories are commonly used forms of electrical connectors that are often used for communications, networking, and video applications. They consist of a variety of styles, including high-density, standard, filter, combination, and waterproof. This type of connector has been around for many years and initially comprised variants offering 9.15, 25, 37, and 50 ways. Since their introduction, there have been many new varieties added to the range, including versions with smaller contacts, allowing for 15, 26, 44, 62, and 78 ways in the same shell sizes.

Which D-sub connector types are available?

There are many types of D-sub connector on the market, which can be differentiated through factors such as the number of pins, the connection method, and their maximum current capacity.

For example, standard D-sub connectors can have pin counts ranging from 9 to 50, while high-density D-sub connectors can have between 15 and 78 pins in different configurations.

D-sub connectors can also feature different termination types, including crimp, screw, solder, and with straight or angled terminals. They can even host different connections within one shell in the form of combination D-sub connectors, which can be used in applications requiring signal, power, and coaxial connections at the same time.

For more challenging settings, where the connection requires a higher level of protection against water, dust, and other potential interferences, it’s also possible to opt for a waterproof D-sub connector (typically with a minimum rating of IP65). When additional security is needed, you may want to purchase a D-sub connector with a tougher hood or backshell, or invest in further protective hardware like caps and locking solutions.

Whichever type of D-sub miniature connector you’re searching for, we’re confident that you’ll find what you need here at Northern Connectors.

Why choose us?

At Northern Connectors, we combine an unbeatable range of circular connectors with industry-leading customer service. We work closely with many of the sector’s most trusted manufacturers to provide customers from all industries with the products they need, when they need them.

With more than 35 years of industry experience on our side, we are able to offer responsive, tailored customer support according to your requirements, and can advise you on any queries you might have. Here are some of the benefits of shopping with Northern Connectors:

What Connector Type Are You Looking For?

Easily find the connection type you need through the categories below:

Get in touch with our connector experts

With over 40 years experience in the industry, we're always happy to share our knowledge and help with connector solutions or product enquiries.

Whether you want to share your specs or already know the connector you require, we're here to advise.