D-Sub Standard & High Density Series

D-Sub Combination Series

IP67 Waterproof D-Sub Combination Series

Han 1A Series

Han-Eco® Series

Han-Modular-Domino Series

Han® Series

Push-Pull Industrial V4 Series

D-Sub Connectors, Housings & Accessories

Industrial RJ45 Ethernet Series

SMS Series

ST Series

GDM Series (Valve Connectors)

G Series

Snap-in ELC (570 Medical Application Series)

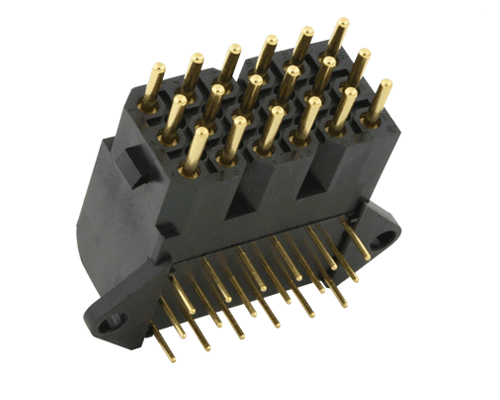

Space-Saving Rectangular Connectors

When there is limited space for components and connections, industrial rectangular connectors can be the optimal way to maintain signal integrity between parts. Being able to house a higher density of contacts within each connector, and making it easier to fit more connectors next to one another, rectangular connectors are very efficient when it comes to space and weight.

This is partly why they can be found in industrial applications from the automotive industry to aviation, where lighter and smaller components that can improve signal transmission are essential. Rectangular connectors also have to be heavy-duty enough to withstand tough operating conditions, such as high power loads and exposure to harsh environments.

The selection of rectangular connectors available from Northern Connectors encompasses a range of features, allowing you to find the product that best meets your specifications from low to high – whether that’s the number of contacts, maximum current or voltage, ingress protection waterproofing, or cable diameter.

What is a rectangular connector?

Connectors are often a common feature in our everyday lives and over time have become smaller and more sophisticated as electronic technology continues to develop, continuously requiring different combinations of parts and appropriate accessories to join them together.

As many different connector types as there are, they’re mostly the same in terms of composition, featuring connector inserts and contacts at the heart where the wires are fixed in place, a housing to carry and protect these inserts, and a cable entry where the housing can allow a cable to pass through.

The shape of the connector and its housing can vary, but one of the most common shapes is a rectangle. This is where the name comes from – a rectangular cable connector is simply a connector with a rectangular housing, designed to connect to a mating surface with the same rectangular shape.

Trapezoidal connectors and D-sub connectors can fall under the umbrella of rectangular connectors. This common shape is useful for making the most of panel space when optimal organisation is needed for maximum productivity.

What are rectangular connectors used for?

Rectangular connectors are perfect for use in the most challenging environments, so are a popular choice in the aviation industry, as well as for the production of household appliances such as dishwashers and refrigerators.

Due to the nature of their design, they offer various locking mechanisms to protect against vibration and shock that are not seen on circular connectors, including:

- Lever action

- Central holding screws

- Latches

- Toggles

Many rectangular connectors offer a high degree of ingress protection and can cater for those applications that require full subversion (IP68) and wash down (IP69K) in industries such as:

- Medical

- Renewable energy

- Off-road

- Lighting

- Instrumentation

- Surveillance

Order rectangular connectors online

Northern Connectors provides an extensive range of rectangular connectors, including products from leading manufacturers such as Conec, Hirschmann, HARTING, and Souriau. Perfect for use in challenging and rugged environments, these products are widely used in a variety of industries.

We can offer expert advice on all your connectors, thanks to 35 years of experience in this field. We are an ISO-9001 certified business, so you can rely on quality service from start to finish. We also provide next-day delivery for items we have in stock, a low minimum order value, and flexible call-off and scheduled order arrangements.

Contact us by calling 01744 815 001, or by filling out our enquiry form or quick quote form to receive a response by email. Our team of experts has the technical expertise to talk through your rectangular connector requirements with you, and will be happy to assist you with placing an order

Frequently Asked Questions

Why use rectangular connectors over circular connectors?

Rectangular connectors are generally more cost-effective to manufacture than their counterparts. They are often reliable, easy to assemble and install and simple to customise for various configurations. This provides more flexibility for wiring paths and cable choices.

Typically being larger, one rectangular connector could do the same job as two or more circular connectors, which simplifies the layout while also allowing for more complex arrangements when the connectors need to be tightly aligned.

Circular connectors can be limited to a top entry style, with one back shell and one thread size, whereas rectangular connectors have better surface mounting capability due to top, side, or angled cable entries with different diameters and housings available.

Not only are the shells easy to stack, but rectangular connectors are also easier to insert correctly on the first try. Even if you attempted it the wrong way up the first time, there would be only one other way to insert it, so you would do so successfully the second time.

Lower costs, greater flexibility, easier handling (including mating and locking) – rectangular connectors are one of the most popular connector types for good reason.

Which rectangular connector do I need?

The primary factor you should consider when choosing a rectangular connector is the minimum electrical performance you require. Every connector should come with a current rating that tells you the maximum capacity for the connector and each individual pin – this often ranges from 2A to 200A.

While the current is the rate of flow of the electric charge between points of a circuit, voltage is the difference in potential charge between two such points, determined by the spacing of the contacts or pins in the connector. This is often anywhere between 24V to 5,000V.

Since heavy-duty rectangular connectors can accommodate large electrical loads, it’s important to know the electrical specifications for your intended usage. The same applies for the mechanical specifications, as your connectors will need to function properly and safely in its intended setting. The harsher the environment, the higher the IP rating they’ll need.

Similarly, you’ll need to consider the most secure termination and locking mechanism for the use and placement of the connector. The connector can be attached to a conductor to form a terminal in many ways, including clamping, crimping, soldering, screwing, wrapping, insulation displacement, and more. Configure locking mechanisms including hoods with screws, central screws, latches, levers, and toggles.

Not sure which specifications to look for? Northern Connectors can discuss the needs of your project to determine which product has the most suitable features to ensure the best possible performance. You can call or email us for assistance with ordering rectangular connectors.

Why choose us?

At Northern Connectors, we combine an unbeatable range of circular connectors with industry-leading customer service. We work closely with many of the sector’s most trusted manufacturers to provide customers from all industries with the products they need, when they need them.

With more than 35 years of industry experience on our side, we are able to offer responsive, tailored customer support according to your requirements, and can advise you on any queries you might have. Here are some of the benefits of shopping with Northern Connectors:

What Connector Type Are You Looking For?

Easily find the connection type you need through the categories below:

Get in touch with our connector experts

With over 40 years experience in the industry, we're always happy to share our knowledge and help with connector solutions or product enquiries.

Whether you want to share your specs or already know the connector you require, we're here to advise.