M12 Series

M12 Stainless Steel Series

M12 Power Series

M12 A-Coded Series

M12 X-Coded Series

M8 & M12 Washdown Series

M12 A-Coded (713, 763 Series)

M12-B Coded (715 | 766 Series)

M12 D-Coded / M12 X-Coded (825 | 876 Series)

M12 A-Coded Food & Beverage Series

Hirschmann M12 A-Coded Cable Connectors (E-Series)

M12 S-Coded / M12 K-Coded (814, 824 Series)

M12 T-Coded / M12 L-Coded (813, 823 Series)

A Wide Range of M12 Connectors

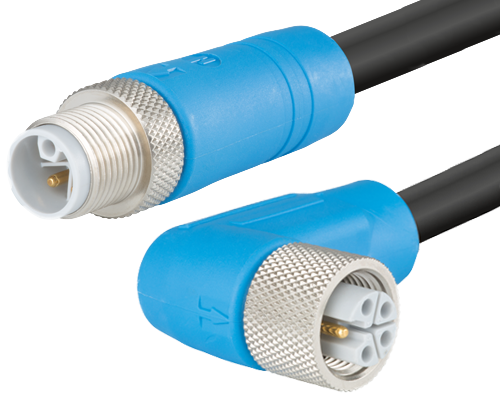

M12 electrical connectors were designed for, and are primarily used in factory automation applications for actuators, sensors, industrial ethernet, and Fieldbus – enabling secure signal and current transmission.

When it comes to finding a ready-to-connect cable, M12 connectors are very versatile and offer options for both cable-to-panel and cable-to-cable requirements.

Field-wireable cable connectors, also known as field-installable connectors, are essential components in engineering and electronics. These cable assemblies offer the user ultimate flexibility with wire termination choices, including screw-clamp, solder, Insulation Displacement Connection (IDC), and crimp connection.

Moulded cable connectors boast a huge variety of options, including single or double-ended variants, shielded or unshielded types, and a wide range of cable jackets, including polyvinyl chloride (PVC), polyurethane (PUR), and thermoplastic elastomer (TPE).

Standard cable lengths for moulded types tend to be 2m, 5m, and 10m; however, any length is possible upon request.

Panel connectors are typically used to connect the front panel buttons, LED, and USB ports to the pins on the motherboard. These are usually provided with dip-solder PCB contacts for mounting directly to the board or with pre-wired, and often potted, contacts.

The portfolio of solutions boasts 3, 4, 5, 8, and 12-way layouts, with a current carrying capacity of up to 16A per contact and data transmission speeds of up to 10 Gbit per second.

The Benefits of M12 Connector Systems

- Compact design – Thanks to its small footprint, an M12 connector lends itself perfectly to industrial applications with space constraints.

- Ease of installation – Designed for quick and easy assembly, a screw-locking mechanism ensures a secure connection, reducing the risk of disconnection caused by external factors.

- Versatility – With various codes catering to different needs, these connectors can address various connectivity requirements, including AC and DC power transfer and industrial ethernet applications.

- Robustness – Rugged and reliable, M12 connectors offer high resistance to shock, vibration, temperature variations, and exposure to dust and water.

- Convenience – Some connectors within this range feature innovative push-pull technology, making it easier to integrate devices, secure them, and save time. And whether you need a sturdy male connector or the corresponding female connectors, connectivity solutions can be tailored to your specifications.

Types and Uses of M12 Connectors

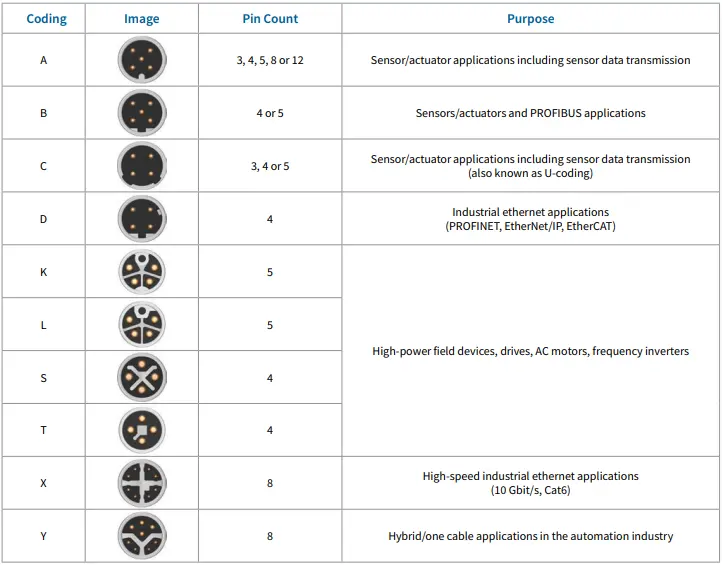

M12 connectors are coded in various ways to avoid mis-mating and to fulfil customers’ demands in terms of international standards. The coding is offered by a variety of notches in the contact bearer, which determines the type.

Common M12 connector coding includes:

- A-coded: Actuators, sensors, and motors

- B-coded: Network cables for Fieldbus systems

- C-coded: AC sensors and actuators

- D-coded: Ethernet applications (high-speed data transfer up to 100Mb)

- K-coded: AC power transmission

- L-coded: DC power transmission

- S-coded: Power transmission (a newer variant of C-coded)

- T-coded: Power transmission(a newer variant of A-coded)

- X-coded: Ethernet applications (high-speed data transfer to 10Gb)

M12 Connectors for Specific Applications

M12 connectors are found in everything from agriculture, alternative energy, communications, and transportation to factory automation applications, measurement & control, and robotics.

While standard circular connectors come in handy for rugged computing in harsh environments, M12 electrical connectors are purposely designed for washdown and corrosive environments – protecting against loose connections and providing a waterproof seal.

How Do I Order M12 Connectors?

Ordering M12 electrical connectors couldn’t be easier than at Northern Connectors.

Our range of M12 connectors includes male and female connectors with straight or right-angled connection options.

Browse our range of connectors in full and click through to find out more about the product’s specifications.

Once you’ve decided on the perfect M12 connector with the correct pin count for your needs, the next step is to request a quote. You can do so by clicking the ‘Quick Quote’ button on the right-hand side of your screen.

Alternatively, if you’d like an expert opinion before you purchase M12 connectors, you’re welcome to call us on 01744 815 001.

Frequently Asked Questions

What Are M12 Connectors Used For?

An M12 connector is a circular connector with a 12mm locking thread, widely recognised for its compact size and excellent durability.

M12 electrical connectors are used predominantly in the factory automation setting, for actuators, sensors, industrial Ethernet, and Fieldbus applications.

An M12 connector for sensor and actuator cable assemblies is typically available in a straight or right-angled configuration. The latter is great for routing cables in tight spaces and preventing excessive bending.

M12 connectors are designed for use in washdown and corrosive environments and are ideal where compact, rugged, and reliable power, signal, and data connections are required.

To find out more about M12 electrical connectors and their applications, don’t hesitate to contact Northern Connectors on 01744 815 001.

What Are The Advantages of Using M12 Electrical Connectors in Harsh Environments?

In the vast realm of connectivity solutions, M12 electrical connectors are often the go-to choice for automation technology and harsh outdoor or industrial environments, and it’s not without good reason.

Depending on which M12 connector you select, it will likely have an ingress protection (IP) code, such as IP20, IP65, IP67, and IP69.

Most of the M12 connectors we supply have an IP67 rating, which means they are protected against dust and temporary immersion up to 1m for 30 minutes.

Boasting a compact design, these coded connectors are an excellent choice for saving space. Surprisingly, they can withstand the harshest conditions – providing reliable connections even when subjected to shock and vibrations.

If you’d like to know more about the M12 electrical connectors we supply at Northern Connectors and, more importantly, how you can benefit from them, speak to the team today.

Is An M12 Connector Waterproof?

Yes – all M12 connectors are waterproof to an extent.

They offer environmental protection against fluid and particulate ingress, making them a mainstay in rugged operations.

An IP65 M12 connector is sealed to prevent dust from entering and protect against water propelled from a nozzle.

M12 electrical connectors with an IP67 rating, on the other hand, are dust-tight and provide protection against immersion up to 1m for a maximum of 30 minutes.

Get in touch for more information about the properties our M12 connectors offer.

Why choose us?

At Northern Connectors, we combine an unbeatable range of circular connectors with industry-leading customer service. We work closely with many of the sector’s most trusted manufacturers to provide customers from all industries with the products they need, when they need them.

With more than 40 years of industry experience on our side, we are able to offer responsive, tailored customer support according to your requirements, and can advise you on any queries you might have. Here are some of the benefits of shopping with Northern Connectors:

What Connector Type Are You Looking For?

Easily find the connection type you need through the categories below:

Get in touch with our connector experts

With over 40 years experience in the industry, we're always happy to share our knowledge and help with connector solutions or product enquiries.

Whether you want to share your specs or already know the connector you require, we're here to advise.