The benefits of modular connectivity

As technology evolves, industrial connectivity has to become more sophisticated to keep pace with the demands. Connector manufacturers work hard to create new and improved solutions that can address the practical needs of their users more effectively than ever before.

One of the most important innovations of this kind has been the emergence of modular connectivity solutions, a product category that has delivered significant benefits in terms of flexibility, cost-effectiveness and manual maintenance requirements. This technology has changed the game for hardware design in many industries, and continues to deliver important benefits today.

Here, Northern Connectors has partnered with Belden - the manufacturer of our popular Hirschmann and Lumberg Automation product lines - to share insights into how these modern modular connectors work, and the various advantages they can deliver for your most important applications.

What are modular connectors? Explaining the basics

Modular connectivity solutions first became popularised in the late 1960s and early 1970s, as a solution to the growing need for more flexible and user-friendly methods of power transfer for industrial systems.

Prior to this, component cables and wires were usually hardwired in permanent configurations, a process that needed to be undertaken by specialist machine builders, who test at each input and output point individually prior to installation. This results in highly complex and non-movable configurations, with a number of important disadvantages:

- Labour-intensive setup process, requiring specialist knowledge and skills

- Complicated system design, with hundreds of interconnecting hardwired connections, making it difficult to troubleshoot and maintain

- Relocating hardwired machinery requires a time-consuming process of disassembly, reassembly, rewiring and retesting by a licensed electrician

Modular connectors emerged as the answer to all of these problems, ushering in a new era of plug-and-play connectivity. The first generation of 7/8” connectors, featuring 10A of power, were the first quick-disconnection solution for power distribution and large sensor/actuator applications, before being superseded by modern M12 power connectors in the last decade.

These modular M12 components reduce connector profiles by up to 50%, while increasing power delivery to 16A. They are designed to offer an ideal balance of size, performance and ease of handling, and their introduction has significantly changed the way that modern electronic hardware setups are configured.

What are the key advantages of modular connectors?

Although hardwired systems are still used in some areas of factory automation, modular connectors have become the go-to option for modern applications that require versatility and flexibility in their installation, testing and maintenance processes.

The key advantages of modular connectors include:

Reduced labour costs

Modular M12 connectors can be simply disconnected and reconnected, just as easily as inserting or removing a plug. This is infinitely simpler than dismantling a hardwired system, and does not require a specialist electrician to complete the job, saving the company time and money.

Faster downtime recovery

Modular connectivity greatly simplifies the maintenance process when a component needs to be replaced. If a cable breaks, you can replace a broken portion of cable, or cut the wire and use a field-attachable connector, while nonfunctioning motors can be easily unplugged, replaced and reconnected. This is significantly quicker than the complete rewiring and dismantling that is often required when dealing with a hardwired system.

Standardised component design

Modern M12 power connectors are all designed to comply with IEC International Standards, eliminating the risk of different manufacturer brands utilising mutually incompatible design standards. It means that power connectors can be purchased from any brand, with the assurance that it will be fully compatible with your existing systems.

Lower risk of human error

M12 connectors utilise a number of easily distinguishable coding styles (S-coded, K-coded, T-coded, L-coded, etc.) to make them easily identifiable, preventing accidental mismatching or miswiring of components.

Streamlined project scheduling

Modular connectivity makes it easier to coordinate your technology design projects, as it allows different components and sections of the system to be created and assembled across a variety of sites, and plugged together simply when everything is complete. This method avoids the need for project designers to “layer” their work in one small area simultaneously, which is necessary when taking a hardwired approach.

Why choose Belden’s modular connectors?

For all of the reasons detailed above, modular connectors are delivering significant and meaningful results in industrial applications across a wide range of sectors, and have become an essential component in many of the core systems upon which businesses rely.

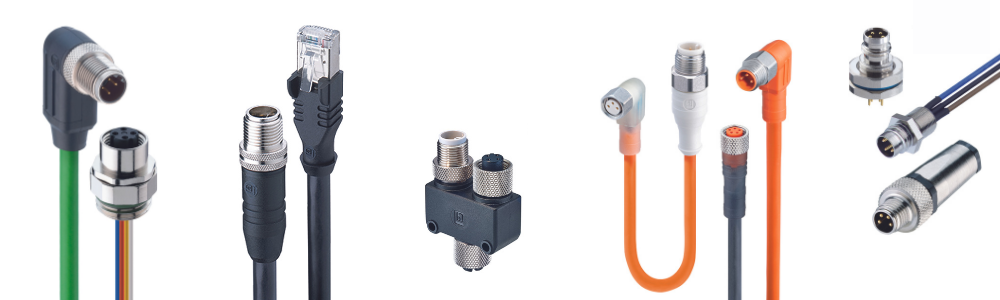

If you are looking for a high-quality modular connector that can help you to unlock all of these benefits for your application, the Lumberg Automation M12 Connectors Series from Belden can be an ideal choice. In addition to the key benefits listed above, Belden’s M12 connectors are able to offer the following additional advantages:

- Belden’s M12 connectors have a diameter of 14 AWG (2.50mm²), rather than the industry standard of 16 AWG (1.50mm²), to ensure better performance. These components are able to carry more current and achieve better derating performance across long distances

- Belden’s connectors are colour-coded and available in four different coding options with different shapes, in order to avoid incorrect mating

- Belden offers a range of M12 power connectivity cabling options, including PVC, PUR and TPE. Moreover, all Belden connectors are UL Listed and meet the requirements of UL 2237, the standard for power distribution on factory machines

Find out more

If you want to know more about Belden modular connectors or need guidance with selecting a suitable solution for your application, Northern Connectors is here to help.

You can explore the Hirschmann and Lumberg Automation sections of our website, call us on 01744 815001, or complete our online contact form and we will be in touch at the nearest opportunity.